TMI-Orion data loggers operate with a dedicated software platform for data acquisition, analysis and visualization, compliant with the following directives and standards:

- FDA 21 CFR Part 11

- EN 554

- ISO 17665

- EN 13060

- EN 285

- EN 868

- EN ISO 15883

- FD X 15-140/IEC 60068.3.11

- Optional IQ/OQ protocol

TEMPERATURE (Pt1000 or thermocouples), PRESSURE, HUMIDITY

Multi sensor data loggers with numerous probe combinations give a cost effective advantage when increasing the number of measurement points.

| Process | Physical parameters | Recommended TMI-Orion models |

|---|---|---|

| Validation of steam sterilization | Temperature and Pressure | PicoVACQ PT, PicoVACQ 1Tc, PicoVACQ 1Td, NanoVACQ 1Tc, NanoVACQ 1,2 ou 3Td, NanoVACQ PT-Tc, VACQ xFlat |

| Routine test of steam sterilization | Temperature and Pressure | NanoVACQ PT-Tc |

| Ethylen Oxyde sterilization | Temperature and Humidity | NanoVACQ HT Ex |

| Depyrogenation | Temperature | PicoVACQ 1Td, VACQ xFlat (with thermal shields) |

| Freeze Drying | Temperature | NanoVACQ 1Tc-2Td, NanoVACQ 1Tc-2Tdi |

| Spray | Temperature and Pressure | PicoVACQ PT |

| Freezer mapping | Temperature | PicoVACQ 1T, NanoVACQ 1T |

| Washing, Desinfection | Temperature | NanoVACQ Flat, MiniVACQ |

| Pouches, containers | Temperature | NanoVACQ Flat |

LIST OF PRODUCTS FOR PHARMACEUTICAL, HEALTH CARE AND BIOTECHNOLOGIES

PicoVACQ Temperature

%20-%20ret.jpg)

Temperature measurement in thermal processes from -70°C to +140°C.

The PicoVACQ Temperature is a very small autonomous temperature datalogger (diameter 15 mm). It is equipped with 1 or 2 temperature sensors at the end of rigid, semi-rigid or flexible probes.

PicoVACQ Pressure and Temperature

PicoVACQ Pressure and Temperature

The PicoVACQ PT is a pressure and temperature data logger, from 0°C to 140°C and up to 15 bar.

With its very small dimensions (diameter 16 mm) it can be placed in sprays or very small containers. It is also used in steam sterilization applications.

NanoVACQ Temperature

NanoVACQ Temperature

The NanoVACQ Temperature is an autonomous data logger equipped with 1 to 3 temperature sensors. Some models are watertight under pressure up to 30 bar.

There are many models available, answering most industrial needs. They vary by number and type of probes, temperature operating range and battery capacity.

Its ruggedness allows temperature measurement in harsh environments.

The models NanoVACQ 1Tc-2Td and the disconnectable probe version NanoVACQ 1Tc-2Tdi are very well adapted for freeze drying process.

%20web(1).jpg)

NanoVACQ Flat

NanoVACQ Flat

The NanoVACQ Flat is a single probe temperature data logger. The temperature probe can be internal or have various sizes up to 100 mm. Its small size, diameter 40 mm and height 11 mm, makes it suitable for washing processes or any sterilization process.

NanoVACQ Pressure and Temperature

NanoVACQ Pressure and Temperature

The NanoVACQ Pressure and Temperature is equipped with 1 pressure sensor and 1or 2 temperautre sensors.

The combination of pressure and temperature measurement is the best way to validate saturated steam sterilization processes.

The standard NanoVACQ Pressure and Temperature models can vary by probe shape or lenght.

NanoVACQ Humidity and Temperature

NanoVACQ Humidity and Temperature

NanoVACQ HT has one humidity sensor and one or two temperature sensors.

It is available in Ex version, which makes it suitable for Ethylen oxyde sterilization validation.

PicoVACQ Humidity and Temperature

PicoVACQ HT has one humidity sensor and one internal temperature sensor. It is available in Ex version for applications in explosive environment, such as Ethylene oxyde sterilization validation.

MiniVACQ Temperature

MiniVACQ Temperature

MiniVACQ is adapted to thermal processes from -40°C to +100°C. It is an ideal temperature data logger for washing-desinfection processes.

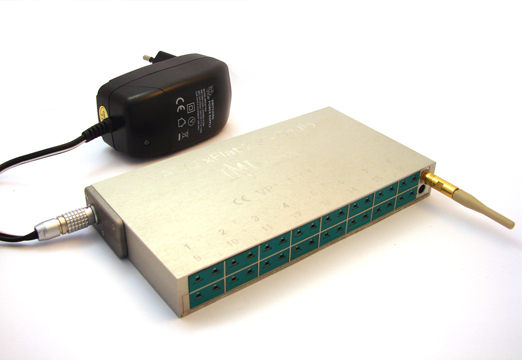

VACQ xFlat

VACQ xFlat

VACQ xFlat is a thermocouple data logger. It can be used for steam sterilization validation if it is placed outside the autoclave. It can also be used inside depyrogenation process (dry heat) where the data logger is protected by a thermal shield.

The VACQ xFlat is available with 4, 8, 16 or 32 thermocouple channels.

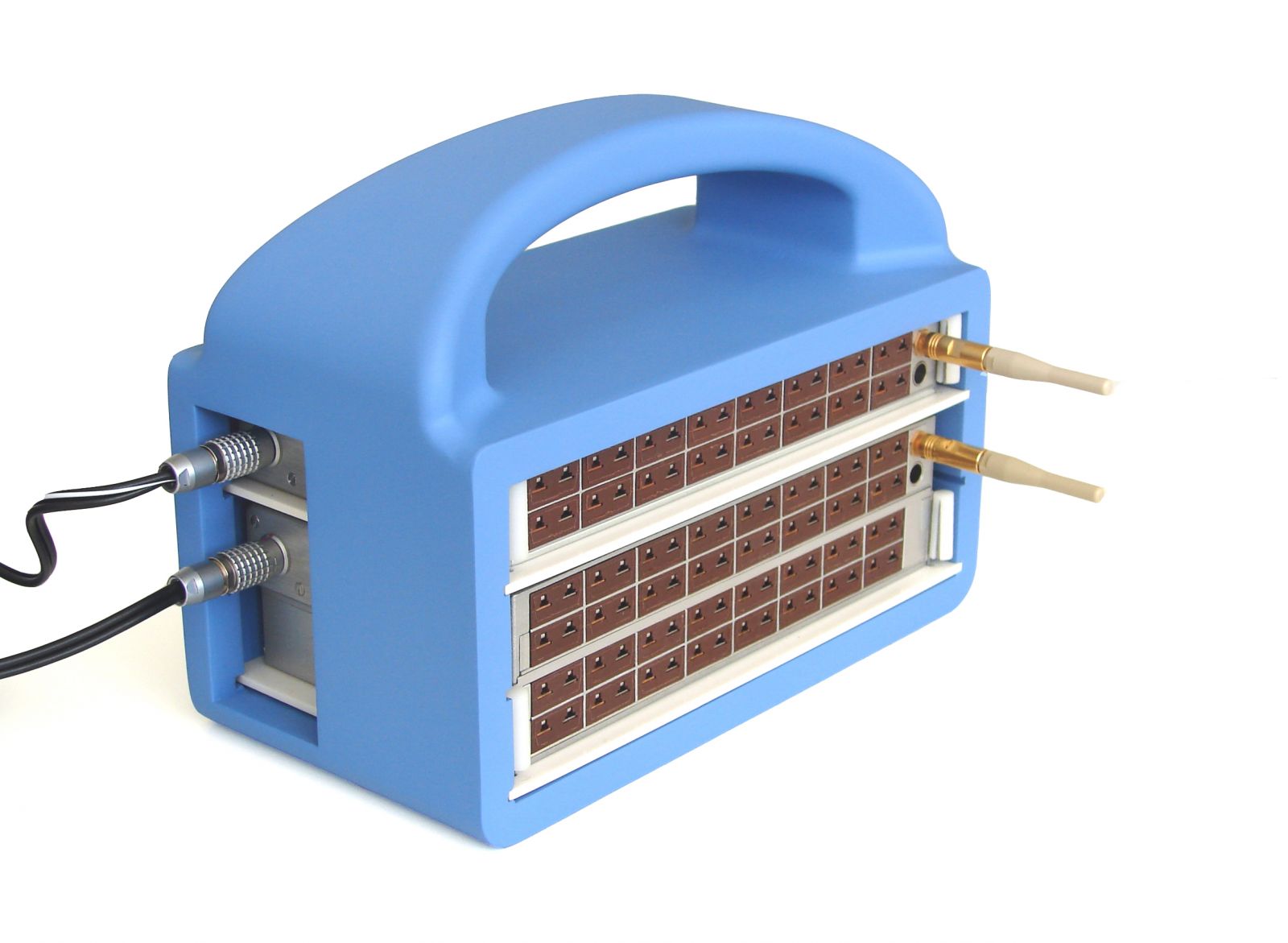

VACQ 3000

VACQ 3000

VACQ 3000 is a pack of 48 thermocouple channels in an easy to store and transport rack for laboratory processes.

The rack can contain a combination of:

1 VACQ xFlat 4.8 Radio + 1 VACQ xFlat 2.8 Radio

or 3 VACQ xFlat 2.8 Radio

The rack is used at room temperature outside the process, but the data loggers can be removed from the rack and used fully autonomously.

FullRadio transmission

FullRadio transmission

The FullRadio option enables set up and reading of data in real time and wireless, by bi-directional radio transmission. It is then possible to start and stop the data logger while it stays inside the industrial process.

FullRadio is adapted to sterilization process validation .

Software

Qlever software platform

Qlever is the software solution for the acquisition, analysis and visualization of the data measured by TMI-Orion data loggers. Qlever operates alone or in combination with one or several industry specific software modules.

It allows the set up and programming of TMI-Orion equipment, collection of data, processing (F0/A0, Vp, saturated steam...), analysis and display of data.

Pharma Module - FDA 21 CFR Part 11

This module meets the requirements of the pharmaceutical industry. It is dedicated to all thermal cycle anaysis.

Creation of an extensive measurement report with statistical calculations detailed by cycles and steps.

LDAP module

The Administrator may use the Microsoft Windows Active Directory LDAP to override Qlever user management. This optimizes consistency in user authorisation management throughout the company information system.

This module requires the Authentication-Tracking module or the Pharma module.

Calibration module

Dedicated to TMI-Orion temperature and humidity loggers calibration process: calibration, adjustment, checking and editing of a report. Expert mode, automatic mode and Manual mode available.

Autoclave Validation Module - ISO 17665/EN 13060/EN 554/EN 285

Data treatment and presentation in an extensive validation report in compliance with ISO 17665 / EN 13060 / EN 554 / EN 285 / EN 868.

Intended for autoclave qualification and sterilization cycles validation (Bowie & Dick, Prions, Helix).

Analysis of vacuum test, pre-treatment phases, plateau phases...

Calculation of saturated steam, calculation of F0 sterilization value, calculation of dynamic pressure, air evacuation calculations for heat penetration analysis in sterilization cycle pre-treatment.

Washing-disinfection Module - ISO 15883

Intended for the analysis and validation of washing-disinfection cycles. Data processing and presentation in an extensive validation report in compliance with ISO 15883.

Mapping Module

Intended for climatic and thermostatic chambers (or any kind of thermal regulation devices such as rooms, ovens, autoclaves...). Data treatment and presentation in an extensive report compliant with FDX 15-140 / IEC 60068.3.11.

Door opening and power cut tests with recovery time calculation.

Creation of relative humidity calculated channels.

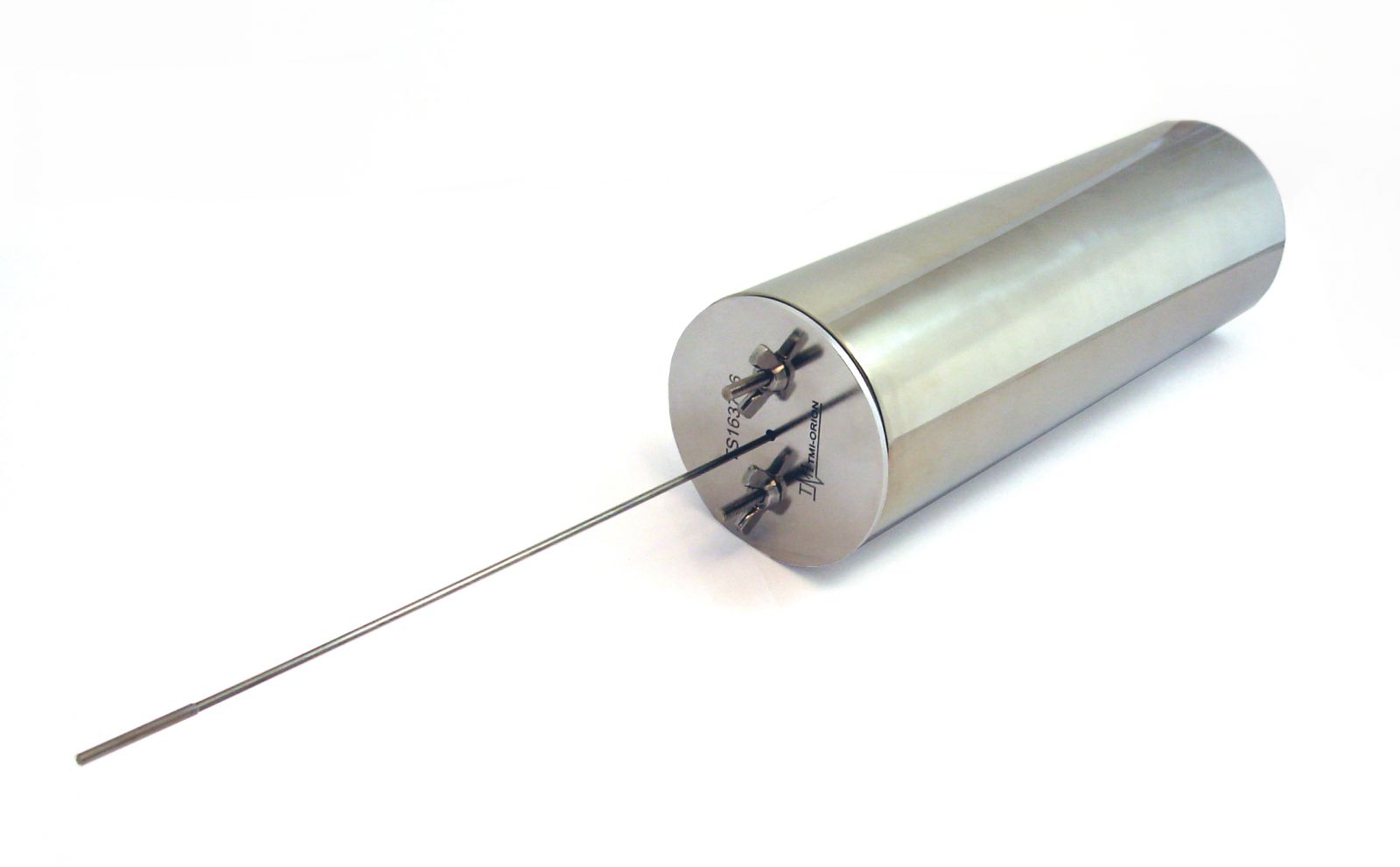

Thermal shields

For any application at a temperature higher than 150°C it is necessary to protect the data logger with a thermal shield.

For any application at a temperature higher than 150°C it is necessary to protect the data logger with a thermal shield.

Connectivity

Communication with the data loggers can be done in various ways:

Communication with the data loggers can be done in various ways:

- Single USB interface

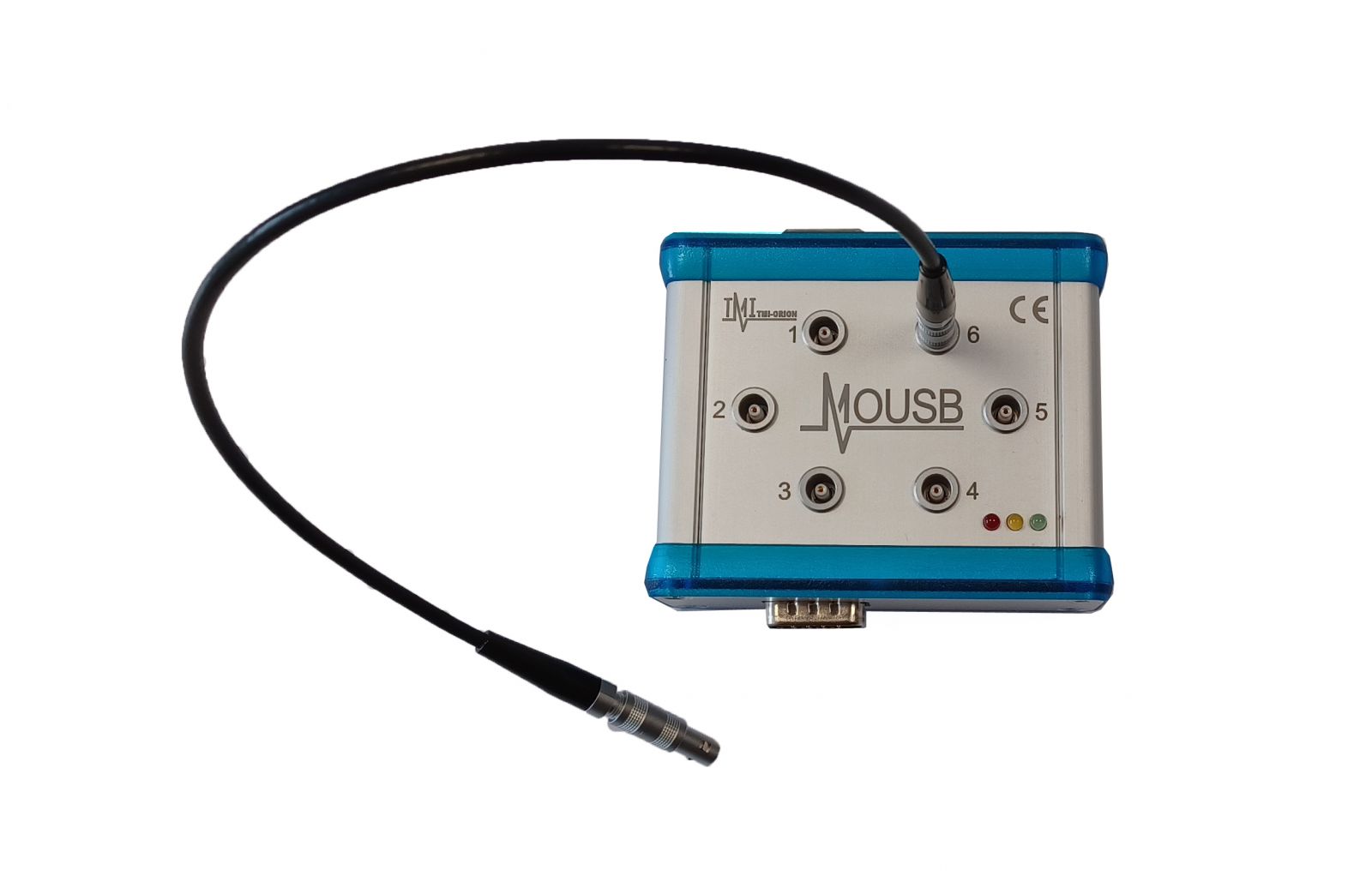

- Multi logger USB interface

- 2.4 GHz radio transmission

Medical and pharmaceutical industries

Solutions for medical and pharmaceutical industries.