TEMPERATURE, AIR FLOW, HUMIDITY, SHRINKAGE, WEIGHT

TMI-Orion has a solution for each of these parameters and allows to record several of them with the same measurement system. This gives you a perfect means to correlate the different parameters.

DRYING PROCESSES

TMI-Orion helps the manufacturers to operate the industrial drying process validation with 2 levels of controls:

• Room: air temperature, room humidity, air velocity

• Drying objects: dimensional variations (shrinkage percentage), internal temperature.

TMI-Orion solutions combine data loggers, a communication interface and Qlever softawre platform.

The loggers mentioned below can be combined together to manage the process parameters.

Air temperature, room humidity and product shrinkage: CeriDry

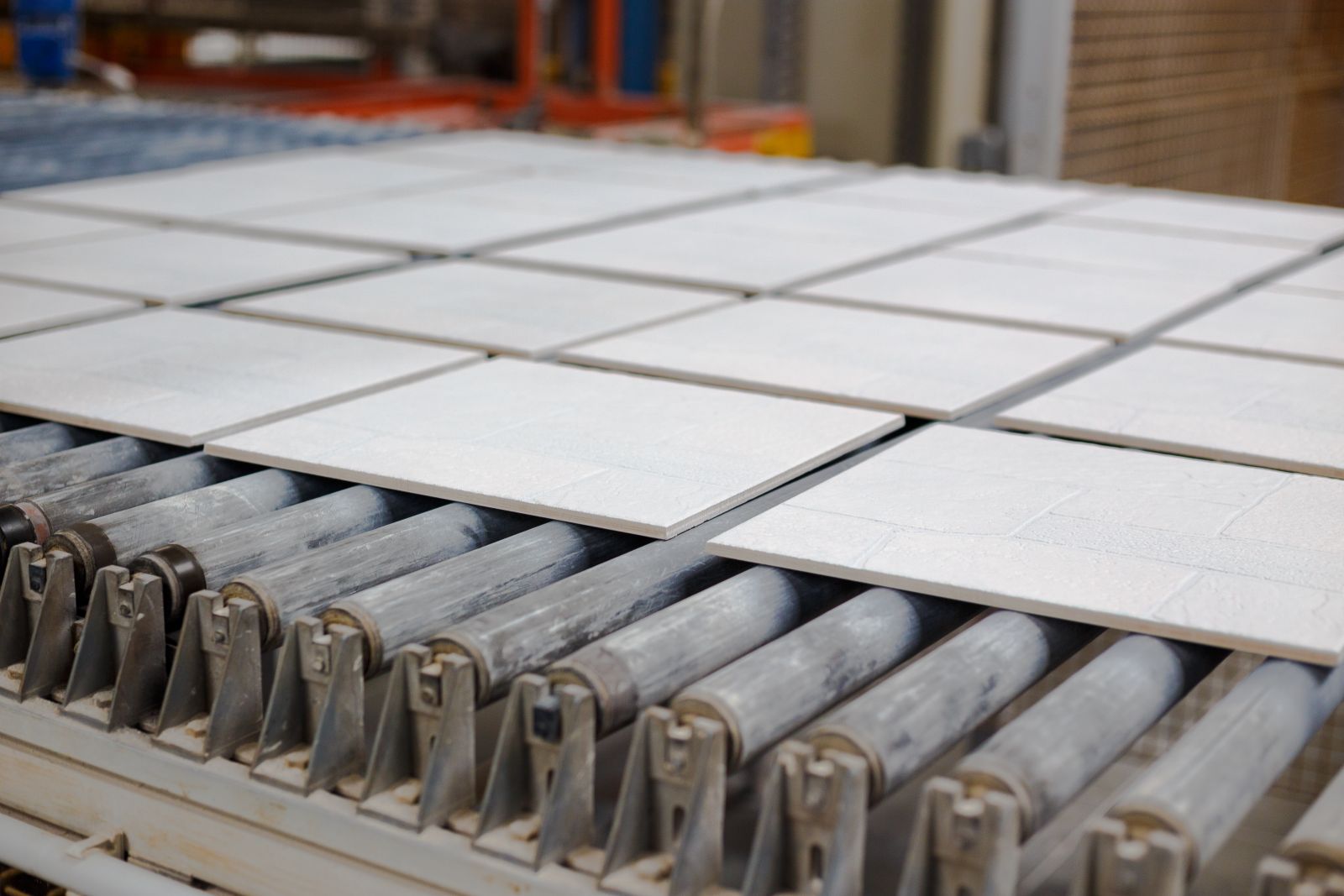

CeriDry correlates the evolution of humidity rate and air temperature with the shrinkage of bricks, tiles or ceramics while they dry.

It also enables the acute evaluation of the drying of a product.

Température, shrinkage: High-T-Dry

High-T-Dry correlates the evolution of air temperature with the shrinkage of bricks, tiles or ceramics while they dry. It also allows the acute evaluation of drying within two parts of the same brick or tile.

The product has been specifically designed to respond to the high temperature drying processes up to 250°C.

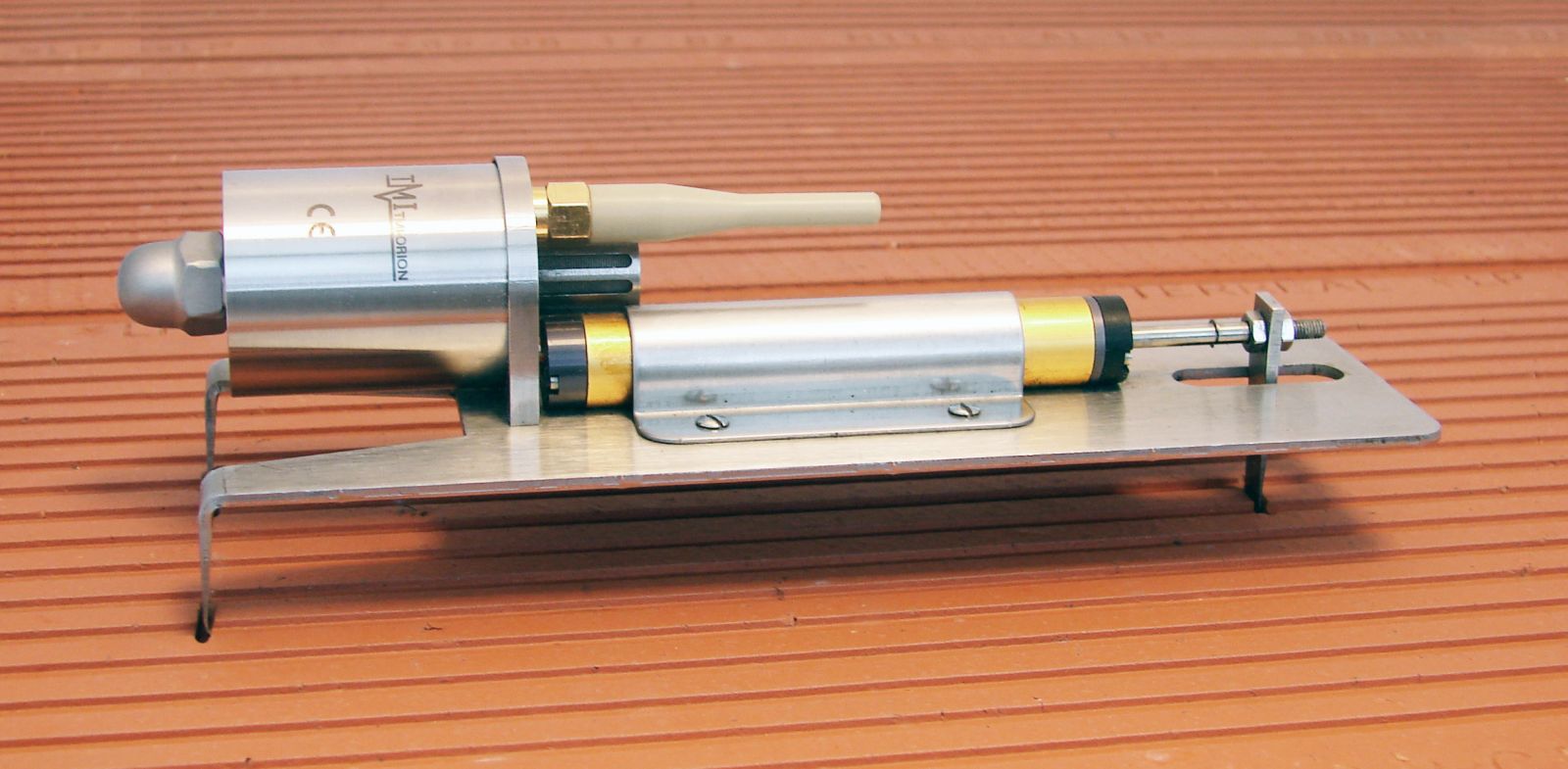

Temperature, air velocity: NanoVACQ Ad-Td

NanoVACQ Ad-Td is an anemometry data logger specifically designed for drying processes in the ceramics industry. It allows a simultaneous measurement of temperature and air flow inside dryers or air flow and temperature inside products.

Weight, Temperature: DryBal

DryBal, is a weight data logger to be used in the drying processes of the ceramics industry.

Temperature mapping in various points of the dryer: VACQ xFlat

VACQ xFlat is available with 4 to 16 thermocouples channels. With its small dimensions, it is adapted to temperature mapping in dryers.

CURING

During the curing phase and the progress of the carts, the temperature profile is carefully controlled. The acquired time-stamped data must be related with the exact position of the controlled cart in the tunnel kiln.

The manufacturer then has to analyze the measured data and take corrective actions throughout the process to reach and maintain the expected quality.

Thermal profile mapping in various points of a cart load during the entire industrial curing cycle: VACQ III

Real time or after the process visualization of the data on the PC, with software description of the kiln and cart load configuration.

8 or 16 thermocouple probes are placed at different points of the cart while the VACQ III autonomous data logger, protected by a

thermal shield, is fixed under the cart.

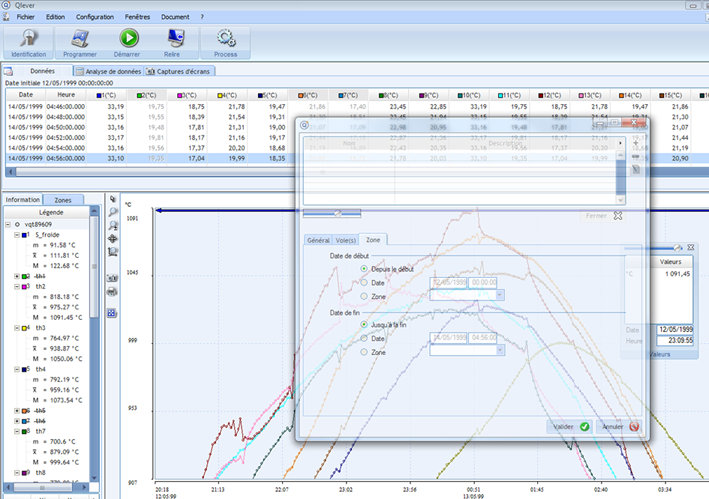

Qlever software - Ceramics module

Qlever is a software solution for the acquisition, analysis and visualization of data measured by TMI-Orion autonomous data loggers.

Ceramics module:

- Kiln description: Kiln length - number, length and duration of pushes,

- Load description: Positioning and 3D visualization of thermocouple probes,

- Kiln configuration: Position of burners, probes, fans….

-

Pushes and events management: Cart thermocouple probes temperature visualization according to cart, localization inside the kiln.

Real time data visualization

The VACQ III, VACQ xFlat and CeriDry are available with Radio option. This allows a real time visualization of the measured data.

Thermal shields

.jpg)

For applications above 140°C, it is necessary to protect the data loggers with a thermal shield.

.jpg)

.jpg)