Pharmacy - Health Care

Pharmacy - Health Care - BioTech

TMI-Orion data loggers operate with a dedicated software platform for data acquisition, analysis and visualization, compliant with the following directives and standards:

- FDA 21 CFR Part 11

- ISO 17665 (formerly EN 554)

- EN 13060

- EN 285

- EN 868

- EN ISO 15883

- FDX15-140 : 2024

- IQ OQ protocol is available as an option

INDUSTRIAL PROCESSES OF MEDICAL

AND PHARMACEUTICAL INDUSTRY

Steam sterilization validation

TMI-Orion Solution

Data loggers

PicoVACQ or NanoVACQ or VACQ xFlat

Software

Qlever software platform

+ Pharma Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module: optional

OR

Qlever Software Platform

+Authentication-tracking Module (FDA 21 CFR Part 11)

+ Calibration Module

+ Autoclave validation Module (ISO 17665 / EN 13060 / EN 554 / EN 285 / EN 868): optional

+ LDAP Module: optional

Connectivity

2.4 GHz radio modem or wired interface for NanoVACQ and VACQ,

Wired interface for PicoVACQ.

Steam autoclaves are used to sterilize products inside vials,

bottles, pouches, and most pharmaceutical and medical

equipment.

During the sterilization process, the temperature must

reach a definite temperature for a determined period of

time. TMI-Orion offers solutions to monitor temperature

inside containers and temperature and pressure inside the

autoclaves, with loggers of different sizes and various types

of probes.

Ethylene oxide sterilization validation

EtO sterilization implies low temperature long lasting

cycles. Ethylene Oxide sterilization validation requires

measuring relative humidity and temperature parameters

inside the chambers wih ATEX compliant data loggers, such

as the NanoVACQ HT Ex.

TMI-Orion has a range of ATEX compliant data loggers

marked “II 1G Ex ia IIC T3 Ga” or “II 1G Ex ia IIC T6 Ga” and

compliant with regulations EN 60079-0 and EN 60079-11.

TMI-Orion Solution

Data loggers

NanoVACQ Ex, PicoVACQ Ex

Software

Qlever Software Platform

+ Pharma Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module: optional

Connectivity

2.4 GHz radio transceiver or wired interface for

NanoVACQ,

Wired interface for PicoVACQ.

Depyrogenation

Depyrogenation, or dry heat sterilization process, uses hot air to reduce the level of pyrogens in static ovens or in tunnels.

In the process, temperature is measured with platinum or

thermocouple sensors, protected by a thermal shield. Data

loggers and thermal shields are selected according to the

specific needs of the process and the characteristics of the

oven or tunnel.

TMI-Orion Solution

Data loggers

PicoVACQ 1Td ou VACQ xFlat with thermal shield.

Software

Qlever software platform

+ Pharma Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module: optional

OR

Qlever Software Platform

+Authentication-tracking Module (FDA 21 CFR Part 11)

+ Calibration Module

+ Autoclave validation Module (ISO 17665 / EN 13060 / EN 554 / EN 285 / EN 868): optional

+ LDAP Module: optional

Connectivity

2.4 GHz radio transceiver or wired interface for VACQ xFlat,

Wired interface for

PicoVACQ

Wired interface for PicoVACQ.

Freeze-drying processes validation

Taking the water out of a product is a way to obtain a more stable product, smaller in volume and weight. This process freezes the product at low temperature, applying vacuum and heat so the ice can evaporate. This process requires measuring the temperature of the chamber and the product.

TMI-Orion provides solutions based on platinum sensors at the end of flexible or semi-rigid probes that can easily fit into small vials through the rubber cap.

TMI-Orion Solution

Data loggers

NanoVACQ 1Tc-2Td or NanoVACQ 1Tc-2Tdi or

PicoVACQ

1Td or PicoVACQ 1Tdi

Software

Qlever software platform

+ Pharma Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module: optional

Connectivity

2.4 GHz radio transceiver or wired interface for VACQ

xFlat,

Wired interface for PicoVACQ.

Mapping of climatic and thermostatic chambers, freezers, cold rooms, etc...

Mapping is necessary to ensure all points of the chamber are at the required temperature.

A data logger operating for days at low temperature is recommended.

TMI-Orion Solutions

Data loggers

NanoVACQ Temperature or PicoVACQ ou MiniVACQ ou

VACQ xFlat

Software

Qlever Software Platform

+ Pharma Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module : optional

OR

Qlever software platform

+ Authentication-tracking Module (FDA 21 CFR Part 11)

+ Calibration Module

+ Mapping module (FDX15-140 : 2024)

+ LDAP Module: optional

Connectivity

2.4 GHz radio transceiver or wired interface for

NanoVACQ and VACQ xFlat,

Wired interface for PicoVACQ and MiniVACQ.

Aerosol spray

TMI-Orion Solution

Data loggers

PicoVACQ PT Ex

Software

Qlever software platform

+ Pharma Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module : optional

OR

Qlever software platform

+ Authentication-tracking Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module: optional

Connectivity

Wired interface

In order to acquire process information during hot filling,

crimping, water bath leakage test and transportation of

products in aerosol spray containers, it is possible to insert a

very small data logger directly inside the spray can.

Washing-disinfection

TMI-Orion Solution

Data loggers

NanoVACQ or NanoVACQ Flat or MiniVACQ or PicoVACQ

Software

Qlever Software Platform

+ Pharma Module (FDA 21 CFR Part 11)

+ Calibration Module

+ LDAP Module: optional

OR

Qlever Software Platform

+Authentication-tracking Module (FDA 21 CFR Part 11)

+ Calibration Module

+ Washing-disinfection Module (ISO 15883)

+ LDAP Module: optional

Connectivity

2.4 GHz radio transceiver or wired interface for NanoVACQ,

Wired interface for NanoVACQ Flat, PicoVACQ and

MiniVACQ.

Washing-disinfection cycles are performed for disinfection purposes or for cleaning loads prior to steam sterilization as this sterilization process is only efficient on clean surfaces.

After the washing-disinfection cycle, the load is inspected and readied for steam sterilization.

Washer-disinfector machines usually use hot sprayed water.

TMI-Orion offers solutions for setup and detailed analysis

of washing and disinfection cycles. Validation reports are

compliant with the ISO 15883 norm.

TMI-Orion PORTFOLIO FOR MEDICAL AND PHARMACEUTICAL INDUSTRY

You will find a choice of loggers covering temperatures from -90°C to +140°C. A thermal shield is necessary to measure

temperatures up to +1200°C.

Sensors are Pt100, Pt1000 or thermocouples. The probes have various forms and dimensions. Sensors can be internal to the

logger, placed at the end of a rigid probe 10 to 100 mm long, or at the end of a flexible or semi-rigid probe, up to 1 meter long.

Depending on the models, you can chose loggers with 1 to 32 measurement channels.

Data loggers

Temperature measurement in thermal processes from -70°C to +140°C.

The PicoVACQ Temperature is a very small autonomous temperature datalogger (diameter 15 mm). It is equipped with 1 or 2 temperature sensors at the end of rigid, semi-rigid or flexible probes.

PicoVACQ Temperature

PicoVACQ Pressure and temperature

The PicoVACQ PT is a pressure and temperature data logger, from 0°C to +140°C and up to 15 bar.

With its very small dimensions (diameter 16 mm) it can be placed in sprays or very small containers. It is also used in steam sterilization applications.

The NanoVACQ Temperature is an autonomous data logger equipped with 1 to 3 temperature sensors. Some models are watertight under pressure up to 30 bar.

There are many models available, answering most industrial needs. They vary by number and type of probes, temperature operating range and battery capacity.

Its ruggedness allows temperature measurement in harsh environments.

The models NanoVACQ 1Tc-2Td and the disconnectable probe version NanoVACQ 1Tc-2Tdi are very well adapted for freeze drying process.

NanoVACQ Temperature

The NanoVACQ Flat is a single probe temperature data logger. The temperature probe can be internal or have various sizes up to 100 mm. Its small size, diameter 40 mm and height 11 mm, makes it suitable for washing processes or any sterilization process.

NanoVACQ Flat

NanoVACQ PT has one pressure sensor and one or two temperature sensors.

The combination of pressure and temperature measurement is the best way to validate saturated steam sterilization processes.

The standard NanoVACQ Pressure and Temperature models can vary by probe shape or lenght.

NanoVACQ Pressure and Temperature

NanoVACQ HT has one humidity sensor and one or two temperature sensors.

The standard NanoVACQ Pressure and Temperature models can vary by probe shape or lenght.

NanoVACQ Humidity and Temperature

PicoVACQ HT has one humidity sensor and one internal temperature sensor. It is available in Ex version for applications in explosive environment, such as Ethylene oxyde sterilization validation.

PicoVACQ Humidity and temperature

MiniVACQ is adapted to thermal processes from -40°C to +100°C. It is an ideal temperature data logger for washing-desinfection processes.

MiniVACQ Temperature

VACQ xFlat is a thermocouple data logger. It can be used for steam sterilization validation if it is placed outside the autoclave. It can also be used inside depyrogenation process (dry heat) where the data logger is protected by a thermal shield.

VACQ xFlat

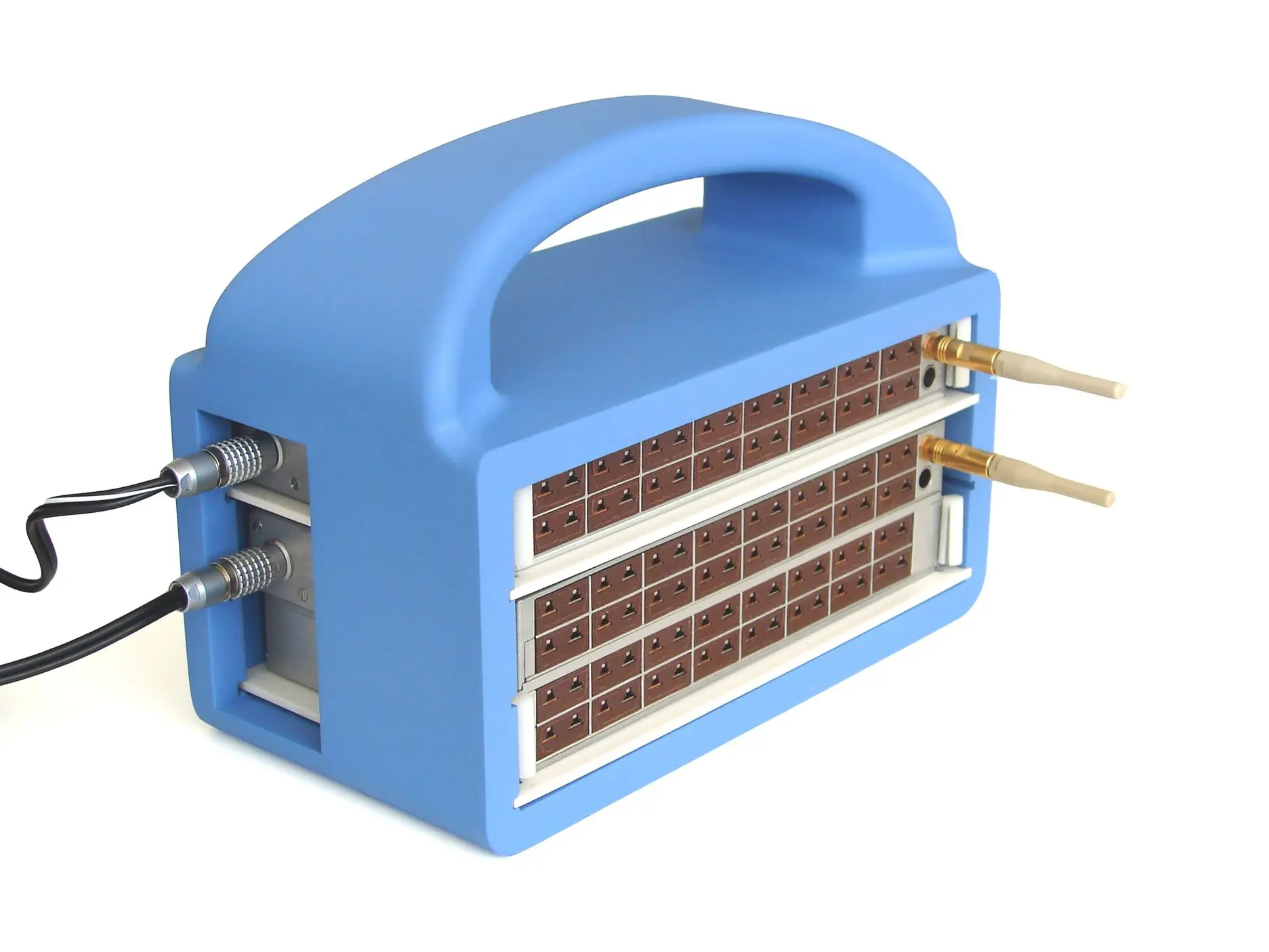

VACQ 3000

VACQ 3000 is a pack of 48 thermocouple channels in an easy to store and transport rack for laboratory processes.

The rack can contain a combination of:

- 1 VACQ xFlat 4.8 Radio + 1 VACQ xFlat 2.8 Radio

- or 3 VACQ xFlat 2.8 Radio

The rack is used at room temperature outside the process.

The FullRadio option enables set up and reading of data in real time and wireless, by bi-directional radio transmission. It is then possible to start and stop the data logger while it stays inside the industrial process.

FullRadio is adapted to sterilization process validation .

FullRadio transmission

Qlever software for pharmaceutical and medical industries

For more information, download our guides

TMI-Orion-Flyer-Pharmaceutical industry and medical sector-English

TMI-Orion-Plaquette-Industrie pharmaceutique et secteur médical-Français

TMI-Orion-DS-Qlever software for pharmaceutical industry-English

TMI-Orion-DS-Logiciel Qlever pour l'industrie pharmaceutique et le secteur médical-Français