Automotive industry

Data loggers for automotive industry

TMI-Orion is offering a large range of temperature, pressure, humidity and air flow data loggers. They help monitoring the manufacturing of subassemblies in the automotive and aeronautic industries.

PROCESSES OF THE AUTOMOTIVE INDUSTRIES

Our solutions include:

· A large range of autonomous data loggers for the measurement of temperature, pressure, relative humidity, anemometry...

· Thermal shields adapted to thermal cycles and dimensional constraints,

· A software for the acquisition, visualization and analysis of measured data.

Examples of applications in the automotive industry

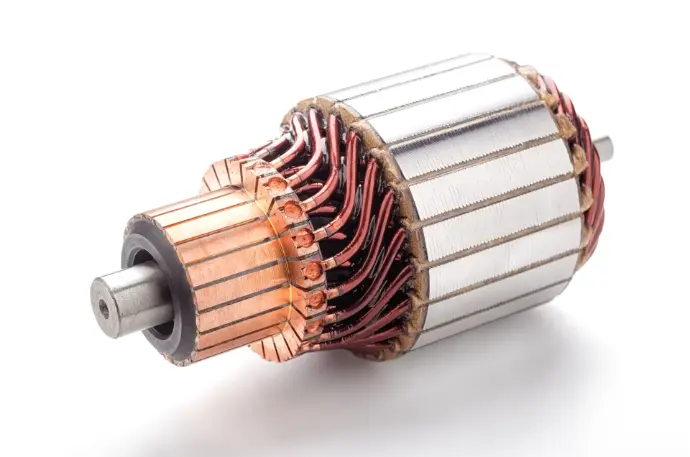

- Rotor impregnation process (temperature monitoring at the heart and on the windings)

- Sensors life test

- Sensors packaging

- Coating on parts (relays, alternators ...)

- Windshield laminated glass autoclaving

- Glass coating (silver, varnish, painting)

- Headlight optical assembly manufacturing

- Molding

- Rubber drying and vulcanization

- Shock absorber parts tempering

- Composite polymerization

- Performance tests

- ...

TMI-ORION PORTFOLIO FOR AUTOMOTIVE INDUSTRY

TMI-Orion data loggers offer numerous solutions for temperature measurement in industrial environments. Thanks to their rugged and, for most of them, watertight structures, they can operate inside high pressure processes.

Please find below a choice of data loggers for automotive industries, measuring temperature, pressure, humidity, anemometry.

Our range of data logger allow temperature measurement from -90°C to +140°C. Above a thermal shield is necessary.

Temperature sensors are Pt100, Pt1000 or thermocouples for high temperatues. The probes have various forms and dimensions. Sensors can be internal to the logger, placed at the end of a rigid probe 10 to 100 mm long, or at the end of a flexible or semi-rigid probe, up to 1 meter long. Depending on the models, 1 to 32 measurement channels are available.

Air flow measurement and temperature is available with the NanoVACQ Anemometer.

PicoVACQ and NanoVACQ are available in Ex version for explosive risk environments.

VACQ and NanoVACQ are available with Radio or FullRadio communication.

Data loggers

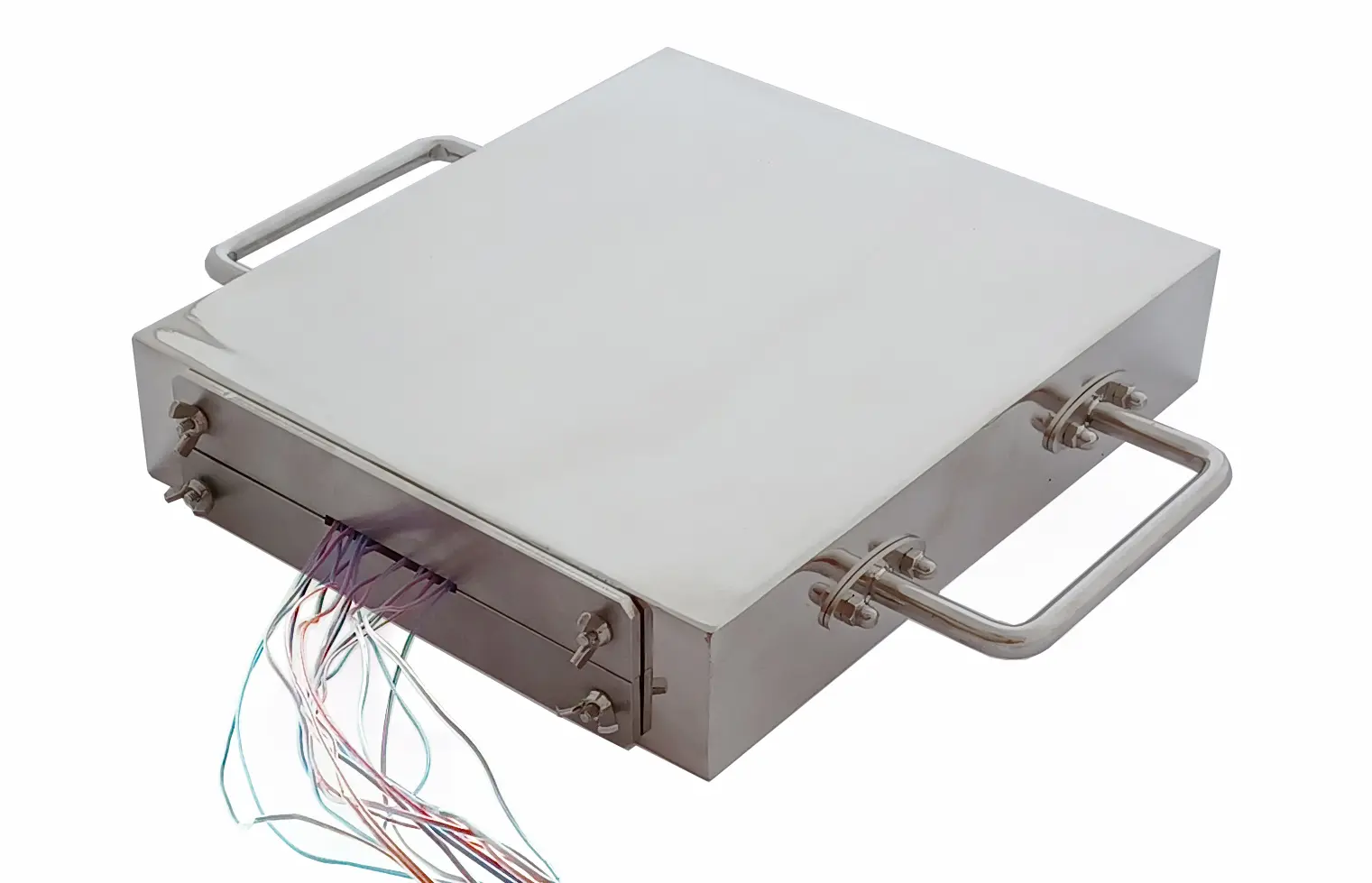

The VACQ xFlat is a flat temperature data logger equipped with 4 to 16 thermocouple channels.

Designed for flat access kilns (20 mm high).

VACQ xFlat

VACQ uFlat

Ultra flat datalogger to measure temperature in 3 points in processes where clearance dimensions are an issue. Thanks to its very small size (height 7.5 mm), it can be used to measure temperature in small clearance ovens.

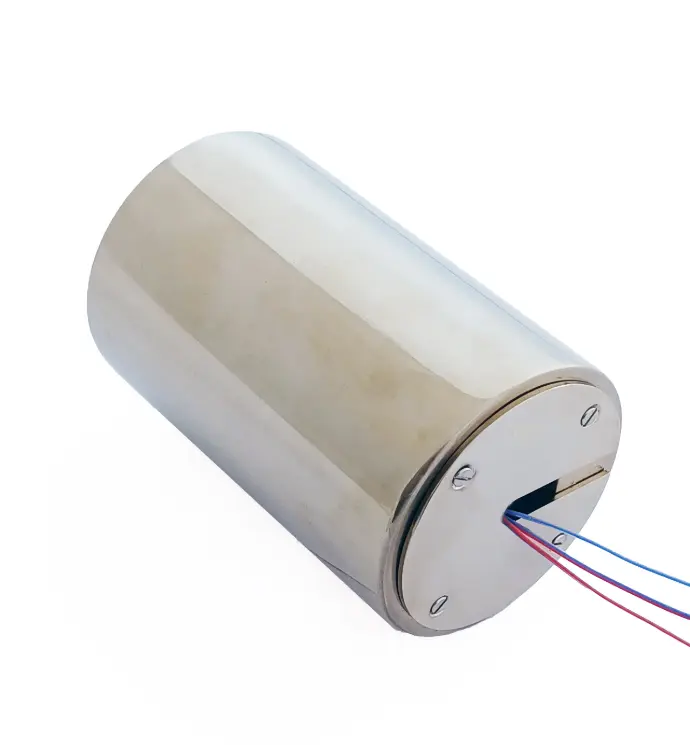

Cylindrical thermocouple data logger (16 or 17 mm in diameter), equipped with a Type K or universal micro-connector.

PicoVACQ Thermocouple

NanoVACQ Thermocouple

Cylindrical thermocouple data logger (31 mm in diameter), equipped with 1 to 3 thermocouple connectors.

NanoVACQ Pressure and Temperature

The NanoVACQ Pressure and temperature is equipped with one pressure sensor and one or two temperature sensors.

The standard models vary depending on the length and shape of the probes.

PicoVACQ Pressure and Temperature

The PicoVACQ PT is a pressure and temperature data logger, from 0°C to +140°C and up to 15 bar.

Up to 256 acquisitions per second.

NanoVACQ Humidity and temperature

The NanoVACQ Humidity and temperature is equipped with one relative humidity sensor and one or two temperature sensors.

The standard models vary depending on the length and shape of the probes.

NanoVACQ Anemometer

The various NanoVACQ Anemometer models allow the measurement of anemometry or anemometry and temperature.