NanoVACQ デフォメーション

トレイ、パウチ、缶またはその他のパッケージの寸法変化を測定します...

調理や滅菌などの熱プロセス中にトレイ、パウチ、缶またはその他のパッケージの寸法の変化を測定します。

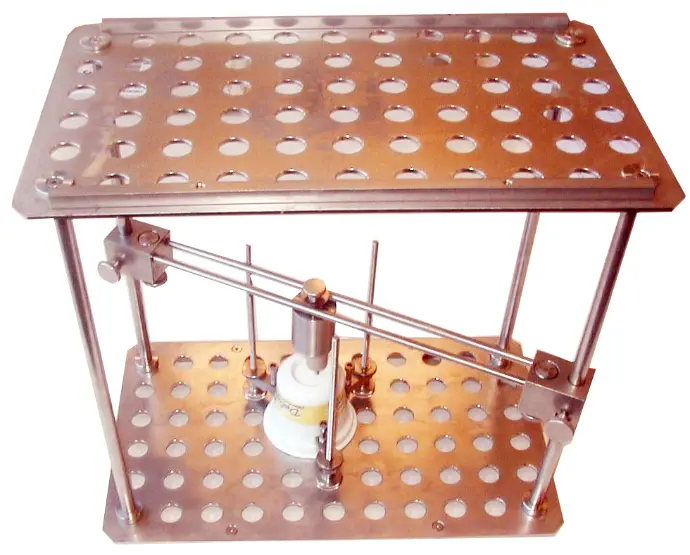

NanoVACQ デフォメーションは、通常または回転式のオートクレーブ用の位置決めと共に使用されます。

このロガーには、校正証明書は提供されません。

Master package deformation during your heat processes by combining deformation / deflection measurement and pressure measurement with TMI-Orion solution.

Measuring package deformation / deflection helps maintaining package integrity, which is critical for safety, shelf life and appearance.

Measure physical deformation (deflection) of the food package, for example, the expansion or contraction of flexible packages in static or rotary processes.

- This delivers the information required to develop your over pressure profile or sealing conditions to prevent package ruptures or paneling.

Measuring package deformation / deflection helps maintaining package integrity, which is critical for safety, shelf life and appearance.

Measure physical deformation (deflection) of the food package, for example, the expansion or contraction of flexible packages in static or rotary processes.

- Check that the equipment (autoclave/oven) maintains the correct pressure during the process,

- Measure the differential pressure applied to the packaging.

Utilisés conjointement, ces deux enregistreurs vous permettent de :

- Correlate pressure conditions with package behavior,

- Design heat processes that are effective and gentle (maintain package integrity),

- Validate and document compliance with regulatory standards (e.g. FDA, EU food safety),

- Optimize overpressure monitoring to match package needs,

- Avoid air trapped inside the chamber (which reduces sterilization efficiency),

- Check the steam was saturated,

- Know if the equipment pressure sensor in chamber if fully functional and representative of load conditions.

NanoVACQ デフォメーションと オートクレーブ用ポジショニングキット

NanoVACQ デフォメーションと回転式オートクレーブ用ポジショニングキット